In a world of rapid changes and technological improvements, businesses that fail to harness and implement continuous improvement (CI) methodologies risk falling behind their competitors.

Nimble businesses can effectively adapt to change, disrupt the status quo and gain a competitive advantage. To stay relevant and be a market leader, businesses focus on achieving Operational Excellence (OE).

Operational Excellence is a state of mind and a complete way of being. OE organisations continually seek to improve processes, materials workflow and endeavour to reach complete waste elimination. There are various methodologies designed to help your organisation tackle process improvement. Each method aims to assist your business to identify process issues, resolve and analyse the success or failure of those changes.

In this article, we examine process improvement methodologies, fundamental principles, advantages and disadvantages

Process Improvement Methodologies

Kaizen

Kaizen is a business strategy focused on making small changes across an organisation’s products, services and people. The purpose is to establish an environment of continuous improvement from the Japanese term ‘change for the better.’ The theory uses statistical tools to measure continuous improvement. A vital component is the focus and encouragement of employee input and creativity to implement change. Fundamental principles of Kaizen include:- Know your customer: Create value for the customer by knowing what they want and how you can improve their experience.

- Let it flow: Everyone in the organisation should aim to reduce and eliminate waste.

- Go to the Gemba: Value occurs when things happen. Focus on that and take it to the next level.

- Empower people: set clear goals for your team and ensure they are supported by the right tools and systems to create success.

- Be transparent: Ensure performance improvements and data is “tangible and visible”.

| Advantages | Disadvantages |

|

|

The Five S’s System (5S)

The 5S system is suited for visual control and lean production as it provides a systematic framework to ensure workplaces are clean, uncluttered, well organised and safe. Furthermore, the aim is to optimise productivity by providing a quality environment that promotes physical and mental wellbeing. As a result, Seiri, Seiton, Seiso, Seiketsu, and Shitsuke (the Five S’s), increase the value of products or services for customers via consistent process improvement. Key principles of the 5s include:- Sort (organise – Seiri): Eliminate and remove all unnecessary materials, tools, parts and instructions.

- Set in order (orderliness – Seiton): Organise the remaining parts and tools neatly for easy use.

- Shine – (cleanliness – Seiso): Conduct clean up campaigns.

- Standardise (Seiketsu): Daily Seiri, Seiton, and Seiso to ensure regular cleaning and maintenance.

- Sustain (discipline – Shitsuke): The 5S is a form of life, and the four S’s must be followed daily.

| Advantages | Disadvantages |

|

|

PDCA – Plan, Do, Check, Act

PDCA is a four-step model (Plan, Do, Check, Act) designed to deliver continuous improvement. PDCA is a repetitive process focused on work processes and the people to provide better products and services to the customer. Fundamental principles of PDCA include:- Plan: Review the current situation, identify the problem and create a plan to address the issue. The plan must include the scale required to resolve the issues, success factors and outline the goals you want to achieve.

- Do: The implementation phase should proceed in small steps and focus on testing the success of the executed actions. Action in small steps and testing ensures you do not lose control of the plan and identify which areas need improvement.

- Check: Critically review the results against objectives. Any problems identified in this phase is an opportunity to improve and change the plan accordingly.

- Act: Reviewing progress and results allows your team to adapt to the new plan and implement changes correctly. As PDCA is circular, you will begin in the latest phase and start from item 1 again.

| Advantages | Disadvantages |

|

|

Six Sigma

Six Sigma is a set of tools and standards for businesses to follow to enable process improvement. Manufacturing and distribution businesses use the Six Sigma methodology for reducing operational waste, enabling cost reduction and quality improvements. It is a problem-solving technique that uses the following data-driven stages to create process solutions. The key stages include:- Define: Work to identify all necessary information and actions to rectify a problem or reach a goal. This stage works to quantify and qualify information, including project timelines, project scope and value stream maps and other measurement tools.

- Measure: Part two will first measure the current process or activity capabilities, then look to see improvements from original measurements with these data sets.

- Analyse: All the stage two data is then analysed to the exact meaning and identify the root cause of the process inefficiencies. The analysis phase requires company-specific Six-Stigma approved data maps to be completed along with the formal root analysis before moving to stage 4.

- Improve: Generally using a Design of Experiment plan, companies will isolate the factors which have contributed to the problems and outline the variables.

- Control: Using a control plan that outlines improved daily workflows, teams will deploy the new standardised process. The control chart will then track the outcome data from the previous process to the new process allowing for quantifiable comparison.

| Advantages | Disadvantages |

|

|

Cause and Effect Analysis

Cause and Effect Analysis is a mind mapping tool to identify all likely causes of a problem and related factors. The methodology often uses a fishbone diagram to discover the root problem, possible bottlenecks in the process and other interrelated causes. The primary principles include:- Identify the problem: Identify the main problem, who is involved, and where it occurs.

- Discover all major related factors: Review systems, processes, culture, equipment, and materials that contribute to the main problem.

- Identify possible causes: Brainstorm and list all the causes related to major factors impacting the main problem.

- Analysis: Review the diagram and identify the following steps to assess the major factors and causes. This can involve surveys, interviews and focus groups on testing the possible causes contributing to the root cause.

| Advantages | Disadvantages |

|

|

SIPOC Analysis

SIPOC Analysis (Supplier, Inputs, Process, Output, Customer) provides a high-level process summary. Often used to scope large projects in the initial planning and design phase when detailed mapping is not yet needed. Used in a table form, businesses can map the inputs and outputs of multiple or singular processes and the associated goals. The five areas of the diagram will include- Supplier: Identify the inputs of a process.

- Input: Resources, materials, technology and equipment needed to complete the process.

- Process: Detailed description of the steps of inputs and outputs involved in the process.

- Outputs: End result of operations (product and services).

- Customer: Recipient of the outputs.

| Advantages | Disadvantages |

|

|

Value stream mapping (VSM)

Value stream mapping is the detailed visualisation of all steps from the flow of goods from the supplier, production to the end output and delivery to the customer. All essential steps in the workflow are mapped out from start to finish. Value stream focuses on the flow of materials, analysing everything that the customer is willing to pay for and sees value in. Using a set of symbols in the mapping process, items are marked as adding value or not from the customer’s standpoint. The key principles of VSM are:- Identify what is involved in satisfying the customers need.

- Establish the systems, processes and technologies that are involved in meeting the customers need.

- Clearly identify where values streams meet.

- Using all the items above, visually outline processes to identify process improvements to satisfy the customer’s needs.

| Advantages | Disadvantages |

|

|

Total Quality Management (TQM)

Total Quality Management focuses on instilling a culture that focuses on customer satisfaction. All organisation members must participate in and are accountable for improvements and quality management across processes, products and services. The eight principles of TQM are:- Customer-focused: Quality of service is determined by the customer’s feedback.

- Employee involvement: Every single member of an organisation is accountable for the quality of products and services.

- Process centred: Every activity must is clear and identifiable processes.

- Integrated systems: Quality management is achieved with an integrated system.

- Strategic and systematic approach: All goals need to be linked to the company’s strategic vision.

- Decision making based on facts: Decisions are based on customer retention, customer feedback from surveys and reviews, sales data and operational figures.

- Communication: Any change requires effective communication, and each staff member must be aware of the reasons for change, level of involvement and time objectives.

- Continuous improvement: All employees must continually strive to improve the quality of products and services to achieve a competitive advantage.

| Advantages | Disadvantages |

|

|

Kanban Process Mapping

Kanban is a workflow management technique that focuses on defining, managing and improving services via visualising work and continuous improvement. The principles of Kanban can be broken down into two categories, change management and service delivery principles:

Change Management:

- Identify what you do now: Kanban identifies the value of current processes. The focus is to identify areas of improvement without removing the entire service delivery framework.

- Agree to small incremental changes: Large sweeping changes are discouraged due to the cultural resistance, fear, uncertainty and risks these changes create.

- Leadership at all levels: Encompanses consideration and involvement of every staff members insights and behaviours to reach optimal performance.

Service Delivery Principles:

- Customer-centric approach: Meeting and exceeding the customer’s expectations should be the centre of all organisations.

- Manage the work: Involves the empowerment of employees to self-organise their work.

- Continuously review network services: Continuously evaluations are required to assess the effectiveness and efficiency of processes.

The primary advantages and disadvantages of Kanban Process Mapping include:

| Advantages | Disadvantages |

|

|

How to identify which method is best for your business

Although each of the methodologies shares common characteristics and goals, each technique will suit a businesses requirements differently.

To identify which methodology is best suited for your business, refer to the fundamental principles and how each method creates change. These differences include;

- Establishing frameworks to create lean process improvement;

- Focus on strengthening company culture to ensure process improvement; and

- Assist workflow management via mapping out goals and intended outcomes.

When process improvement becomes part of every day, it never ends. Nimble businesses establish cultures that measure results, can strategically modify plans and are supported by innovative tools. To overcome the weaknesses of any methodology, your business will need the support of integrated systems, data and training to maximise growth.

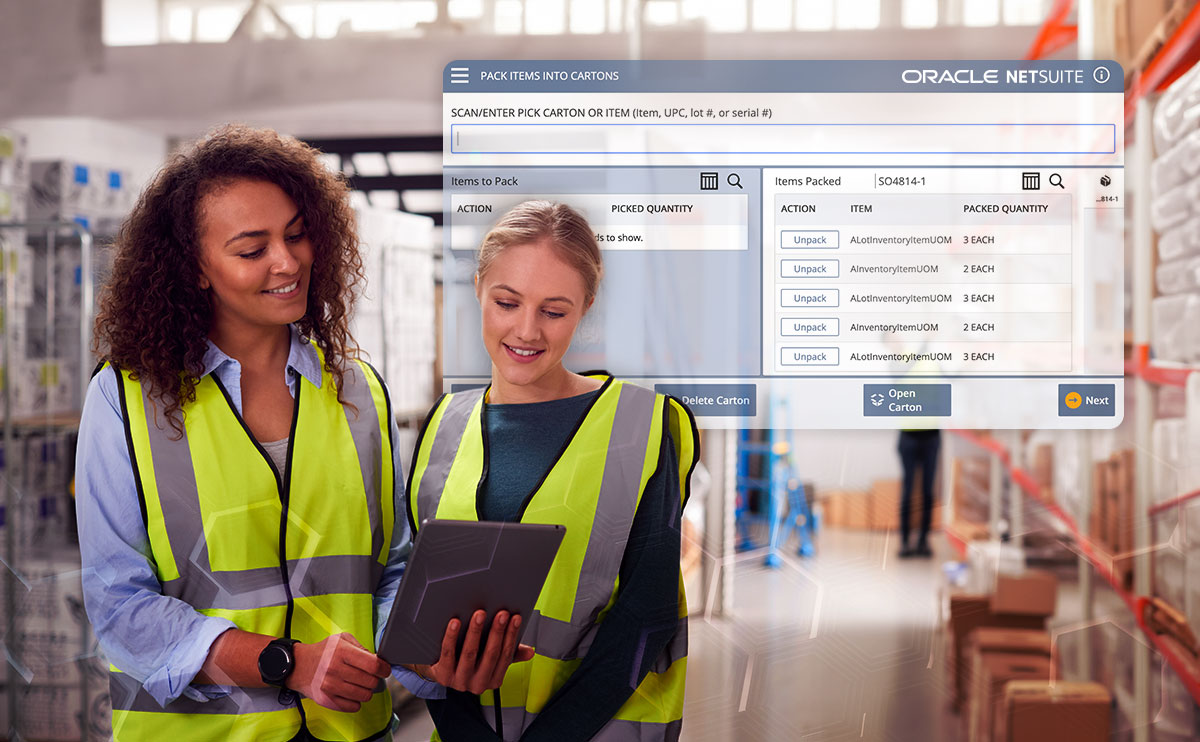

At Klugo we’ve helped hundreds of businesses achieve Operational Excellence via lean process methodologies and world-leading technologies. Schedule a call with our team today and start the journey towards Operational Excellence.

About Klugo

NetSuite + NextService

Klugo’s vision is to unlock the full operating potential of our customers to maximise the value of their business. We do this by helping our customers achieve operating excellence using NetSuite + NextService, the world-leading cloud ERP and FSM business platform for small-to-medium-sized businesses.

Need a specialist’s free advice?

Feel free to call an expert in operational excellence today. Find out how cloud-based technology can support and quickly adapt to your growth strategies.